How a Hydrogen Refuelling Station Works

Hydrogen refuelling stations play a vital role in the development of low-carbon mobility and lie at the heart of these initiatives. But how do they work? Discover the anatomy and operation of hydrogen refuelling stations.

Hydrogen Stations in Europe: An Overview of the Regulatory Framework (AFIR)

The Regulation on the Deployment of Alternative Fuels Infrastructure (AFIR) is part of the “Fit for 55” package. Presented by the European Commission on 14 July 2021, this legislative package is designed to help the EU reduce its net greenhouse gas emissions by at least 55% by 2030, compared to 1990 levels, and achieve climate neutrality by 2050.

Regarding hydrogen mobility, the regulation mandates the deployment of hydrogen refuelling stations for both cars and trucks in all urban nodes and every 200 km along the main transport corridors of the TEN-T core network.

“To ensure interoperability, all publicly accessible hydrogen refuelling stations should, at a minimum, supply gaseous hydrogen at 700 bar. Infrastructure deployment should also take into account emerging technologies, such as liquid hydrogen, which offer greater range for heavy-duty vehicles and are expected to become the preferred technological option for certain vehicle manufacturers,”

the regulation states. It also places strong emphasis on user experience, specifying that payments must be easy and transparent for all users.

Did you know ?

AFIR was officially adopted by the European Council on 25 July 2023.

The Different Types of Hydrogen Refuelling Stations

Distinguishing Between Two Types of Hydrogen Refuelling Stations

There are two main categories of hydrogen refuelling stations:

-

Hydrogen production and distribution stations, which integrate an on-site electrolyser. These stations produce hydrogen through the electrolysis of water—a process that uses electricity to split liquid water into oxygen and gaseous hydrogen.

-

Hydrogen distribution-only stations, which are supplied with hydrogen from an external production source.

Electrolyser-Based Production on the Rise

An increasing number of hydrogen production projects based on electrolysis are emerging across Europe. This development is expected to:

-

Reduce the cost of hydrogen per kilogram,

-

Improve the overall life-cycle performance of hydrogen-powered vehicles.

Life-Cycle Impact of Hydrogen-Powered Vehicles

The estimated life-cycle greenhouse gas emissions (in CO₂-equivalent) for a utility vehicle are as follows:

-

42 tonnes of CO₂-eq when powered by diesel,

-

38 tonnes when using hydrogen produced via steam methane reforming (SMR) and transported by truck at 200 bar,

-

31 tonnes when using hydrogen produced via SMR and transported at 500 bar,

-

15 tonnes when using hydrogen produced via electrolysis powered by the grid energy mix.

- 11 tonnes when using hydrogen produced via electrolysis powered by renewable electricity (green hydrogen).

(Source – Life Cycle Assessment of Hydrogen)

How Refuelling Stations Works

Whether it is a production and distribution station or a distribution-only hydrogen dispenser, the operating principles of a hydrogen refuelling station remain the same.

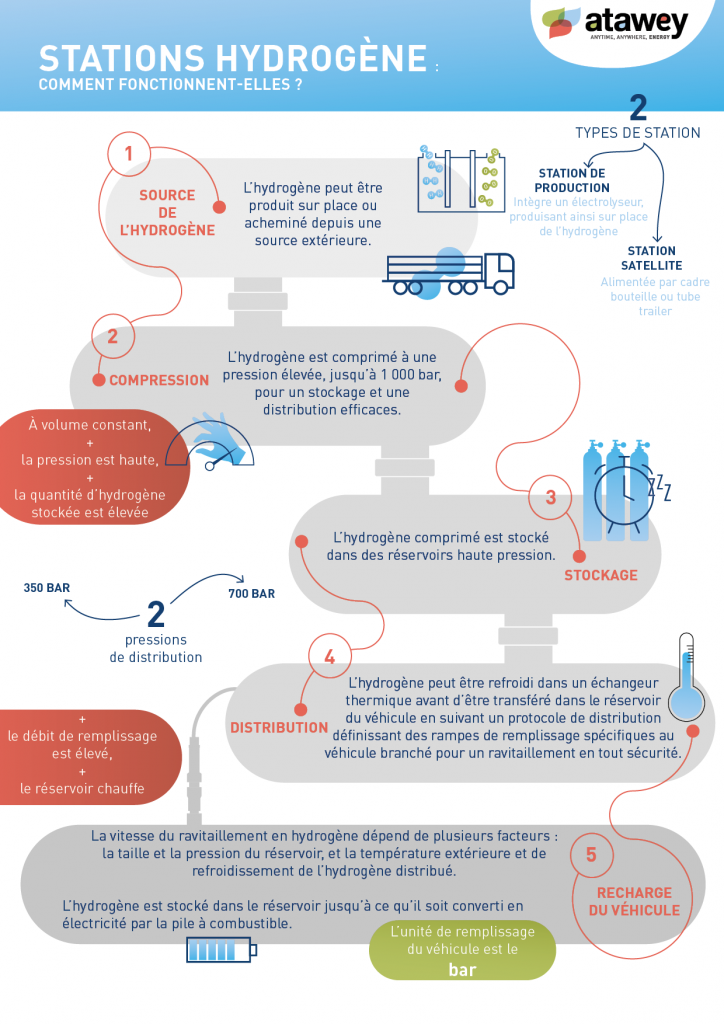

1. Hydrogen Source

Hydrogen can either be produced on-site (using technologies such as electrolysis) or delivered from an external production facility.

2. Compression

The hydrogen is compressed to high pressures—up to 1,000 bar—to ensure efficient storage and dispensing. Various compression technologies are used depending on the required operating pressure and flow rates.

3. Storage

The compressed hydrogen is stored in high-pressure tanks made from reinforced composite materials or steel. Inventory management is a core component of the station’s control system, ensuring reliable operation and optimal usage of available hydrogen.

4. Dispensing

Before being transferred to a vehicle’s tank, the hydrogen may be cooled in a heat exchanger. The refuelling process follows a specific dispensing protocol, which defines pressure ramps tailored to the connected vehicle to ensure safe and efficient fuelling.

To guarantee compatibility between stations and vehicles, standardised dispensing protocols have been developed. The two main protocols currently in use are:

-

H70 / H35 standard: These refer to dispensing protocols at 700 bar and 350 bar, respectively. They correspond to the service pressure of vehicle hydrogen tanks.

The choice of pressure is determined by the vehicle manufacturer based on factors such as driving range requirements, onboard storage volume, and vehicle mass. - SAE J2601 Standard: This standard defines hydrogen refuelling protocols at 350 bar and 700 bar, suitable for both light-duty and heavy-duty vehicles.

J2601 also establishes different filling ramp strategies tailored to vehicle types: the MC Formula and the lookup table method.

Atawey is the first French manufacturer to have integrated the MC Formula into its hydrogen refuelling systems.

5. Vehicle Refuelling

The refuelling process is similar to that of a conventional service station. The user connects the station’s dispensing hose to the vehicle’s hydrogen inlet.

The speed of hydrogen refuelling depends on several factors: the size and pressure rating of the tank, as well as the ambient temperature and the cooling temperature of the hydrogen being dispensed.

Once transferred, the hydrogen is stored in the vehicle’s tank until it is converted into electricity by the fuel cell.

Did You Know?

Hydrogen vehicles are refuelled based on pressure in bar, not volume in litres.

And by the way: how does a hydrogen engine work?

Once the hydrogen is on board the vehicle, it reacts with oxygen from the ambient air inside a fuel cell. This reaction generates electricity, which then powers the vehicle’s electric motor to ensure propulsion. And the only by-product of this reaction? Water vapour! That’s why it’s referred to as decarbonised mobility.

What Are the Advantages of Hydrogen Compared to Batteries for Cars?

Advantages and Challenges of Hydrogen Refuelling Stations

Hydrogen mobility offers faster refuelling times compared to battery-electric vehicles, extended driving range, and zero tailpipe emissions—except for water. Thanks to hydrogen’s high energy density, the refuelling experience is comparable to that of a traditional fuel station.

Another key advantage is flexibility: hydrogen refuelling stations can be installed close to roadways, improving accessibility for vehicles and supporting the development of a practical refuelling network.

What Are the Disadvantages of Hydrogen?

The deployment of hydrogen refuelling stations faces several challenges, including the high cost of hydrogen production and the need to expand the station network to cover more territories—thereby enabling the widespread adoption of hydrogen-powered vehicles.

To achieve economic viability, the hydrogen sector must scale up industrial production in the coming years. This includes not only hydrogen itself, but also the manufacturing of refuelling stations and all other components essential to the sector’s development, in line with evolving standards and regulations.

Did You Know?

In France, a specific regulatory framework for hydrogen refuelling stations was introduced in 2018 to define safety and risk prevention requirements.