Hydrogen Engine: How Does It Work?

The hydrogen engine is a key solution for decarbonizing intensive mobility. It relies on using hydrogen as an energy carrier and, depending on the technology, produces either no emissions (in the case of a fuel cell) or very few emissions (in the case of a combustion engine), such as CO₂ and nitrogen oxides (NOx).

In this article, we’ll take a detailed look at how hydrogen engines work, their advantages, disadvantages, and their potential to meet today’s environmental challenges.

What is a Hydrogen Engine?

A hydrogen engine converts the chemical energy of hydrogen into mechanical energy to power a vehicle. There are two main types of technologies:

-

Fuel cell systems (also known as FC or Fuel Cell), which generate electricity to drive an electric motor

- Hydrogen Internal Combustion Engine (HICE)

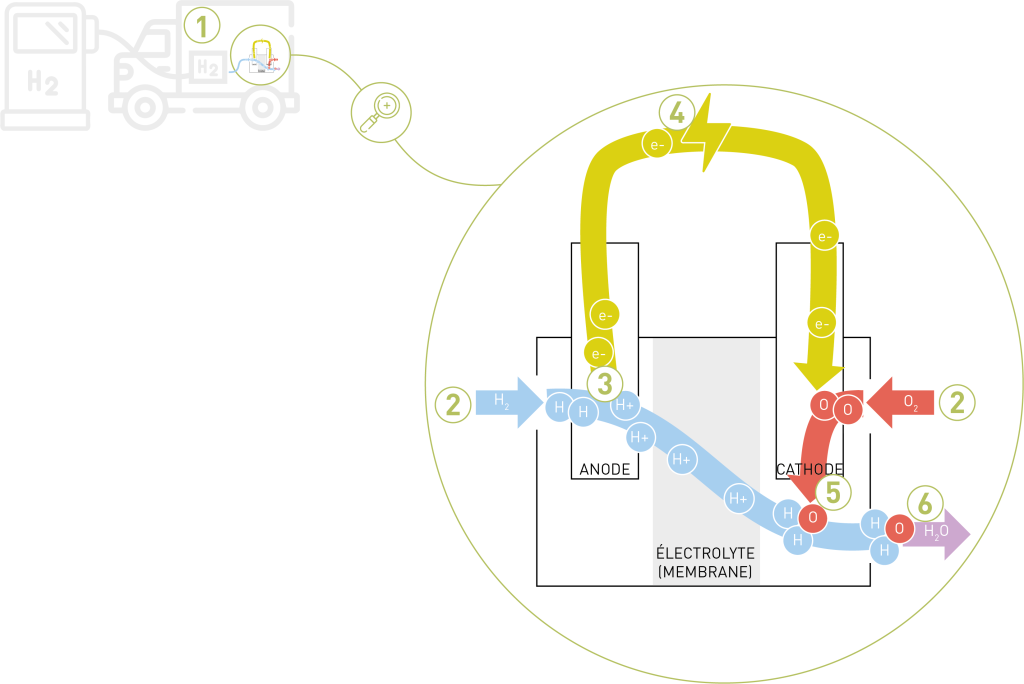

How Does a Fuel Cell System Work in a Hydrogen Vehicle?

The fuel cell [1] is the heart of the system. Today, this is the most widely used technology when it comes to hydrogen-powered vehicles.

Here are the key steps in how a fuel cell works:

- Gaseous hydrogen is stored in the vehicle’s tanks after refueling at a hydrogen station [2].

- Hydrogen is directed toward the fuel cell via the anode, while oxygen from the air enters through the cathode.

- At the anode, a chemical reaction occurs, splitting hydrogen into electrons and protons—a process called redox (oxidation-reduction).

- The electrons travel through an external circuit, generating electricity to power the electric motor.

- Meanwhile, the protons pass through the electrolyte to the cathode, where they react with oxygen and electrons to form water.

- As a result, the only by-product of this reaction is water vapor. Thus, vehicles powered by a fuel cell only emit water vapor from the exhaust.

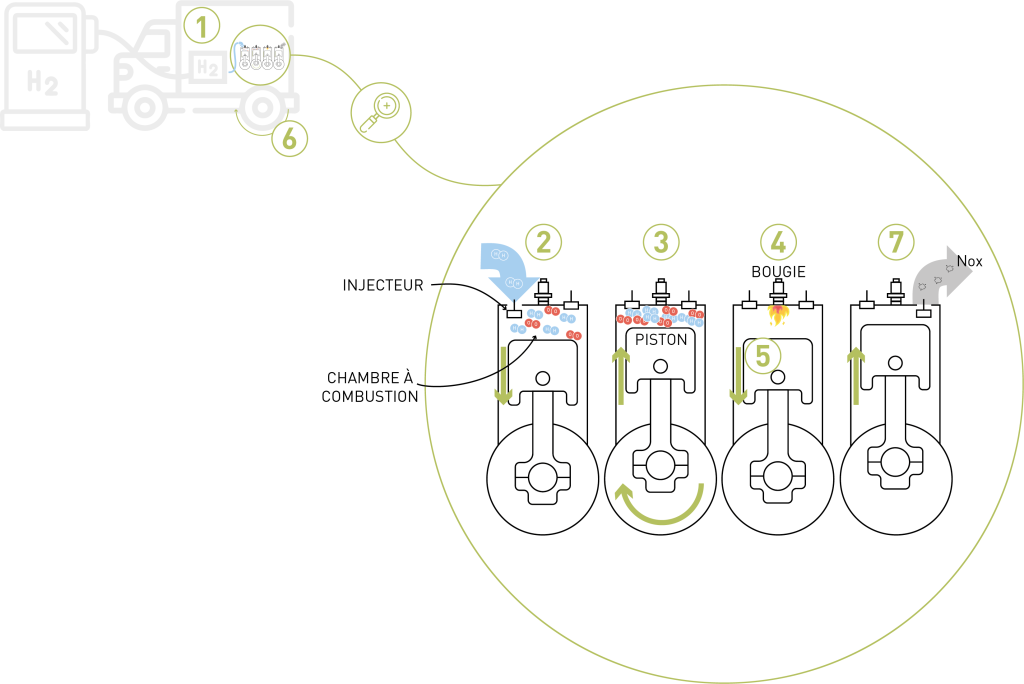

How Does a Hydrogen Internal Combustion Engine Work?

The hydrogen internal combustion engine (HICE) [3] operates similarly to a conventional internal combustion engine. However, instead of burning gasoline or diesel, it burns hydrogen. Here’s how it works, step by step:

- Gaseous hydrogen is stored in the vehicle’s tanks after refueling at a hydrogen station.

- Hydrogen is injected into the engine’s combustion chamber via injectors and mixed with air.

- A piston compresses the hydrogen-air mixture, raising the pressure and temperature inside the combustion chamber.

- A spark plug ignites the mixture.

- When the mixture ignites, it generates heat and energy, pushing the piston upward. This energy is then converted into mechanical motion.

- The force produced by combustion is used to drive the vehicle’s wheels.

- The exhaust valve opens to release the burnt gases—mainly nitrogen oxides (NOx) and, if the hydrogen isn’t pure, potentially some CO₂.

Fuel Cell vs. Hydrogen Internal Combustion Engine: What Are the Differences?

This article compares the advantages and limitations of both technologies: HICE and FC.

If you would like to learn more about the overall pros and cons of hydrogen vehicles, check out our article “Why Choose a Hydrogen Car? Advantages, Disadvantages, and Practical Applications.” [4]

Advantages and Disadvantages of Fuel Cells (FC)

✅ Advantages

- Zero emissions during operation: The only by-product of a fuel cell is water vapor. No greenhouse gases or atmospheric pollutants are emitted.

- Higher energy efficiency than HICE: Fuel cell systems typically achieve an overall efficiency of 40 to 50% [5]. This technology generates electricity directly through an electrochemical reaction, without combustion. Today, the overall efficiency of a fuel cell remains significantly higher than that of a hydrogen internal combustion engine.

- Silent operation: Like electric vehicles, fuel cell systems produce minimal noise and no vibrations, enhancing driving comfort and reducing noise pollution.

- Reduced maintenance: Fuel cell systems have fewer moving mechanical parts compared to combustion engines, leading to lower wear and maintenance needs.

❌ Disadvantages

- High cost: Fuel cells are still expensive due to their relatively young technology and the use of costly materials like platinum.

- Sensitivity to hydrogen purity: Fuel cells require very pure hydrogen (typically over 99.99%) to operate efficiently.

Advantages and Disadvantages of Hydrogen Internal Combustion Engines (HICE)

✅ Advantages

- Mature, well-understood technology: HICE builds on traditional combustion engine designs, making it easier to integrate into existing manufacturing lines.

- Lower production costs: Traditional engine manufacturing doesn’t require expensive materials like platinum, reducing costs.

- Tolerance to impurities: HICE engines are more tolerant of hydrogen impurities, maintaining performance and longevity even with slightly impure hydrogen.

❌ Disadvantages

- Lower energy efficiency compared to FC: Today, hydrogen internal combustion engines (HICE) achieve an overall efficiency of around 20 to 30%, with projections aiming for 50% in the future [6]. Converting chemical energy into heat and then into mechanical energy leads to losses at each stage of the process.

- NOx emissions: While HICE engines do not emit CO₂, they still produce nitrogen oxides (NOx) due to the high combustion temperatures.

- Noise and vibrations: Mechanical processes remain similar to conventional engines, so noise and vibrations are still present, leading to noise pollution and reduced driving comfort.

- Mechanical wear: Numerous moving parts lead to higher maintenance needs, similar to traditional combustion engines.

- Less suited to urban use: HICE engines do not generate electricity for support at low speeds, making them less responsive in urban driving conditions.

Here’s a comparative table summarizing the advantages and disadvantages of each technology:

| Criteria | Fuel Cell Engine (FC) | Hydrogen Combustion Engine (HICE) |

| Local emissions | ✅ None (only water) | ❌ NOx emissions + variable CO₂ (if impure hydrogen) |

| Energy efficiency | ✅ Medium (40–60%) | ❌ Low (20–30%) |

| Noise and vibrations | ✅ Quiet, low vibrations | ❌ Noisy, with vibrations |

| Maintenance | ✅ Reduced (fewer mechanical parts) | ❌ Higher (more moving parts) |

| Hydrogen purity requirement | ❌ Very high (≥ 99.99%) | ✅ Tolerant to 1–2% impurities |

| Production cost | ❌ High (complex technology, rare materials) | ✅ Lower (proven technology, fewer critical materials) |

| Industrial integration | ❌ Less standardized | ✅ Easy integration into existing lines |

| Urban usage adaptability | ✅ Highly responsive | ❌ Less responsive at low speeds |

Retrofitting: Giving a Second Life to Combustion Vehicles

Hydrogen retrofitting [7] involves replacing a traditional combustion engine (diesel or gasoline) with a clean hydrogen-powered system. This solution helps decarbonize existing vehicles without manufacturing new ones and fits into a circular economy and sustainable mobility transition.

Retrofitting a Combustion Engine to Hydrogen: What Are the Options?

- Hydrogen-electric hybrid retrofit (fuel cell-based)

This method removes the internal combustion engine, fossil fuel tank, and exhaust system, replacing them with a fuel cell, electric battery, and one or more high-pressure hydrogen tanks (typically at 350 or 700 bar, depending on the vehicle).

Additional components such as power electronics, cooling systems, and hydrogen-specific safety sensors are also adapted. - Hydrogen combustion engine retrofit (HICE)

The original combustion engine is modified or replaced to run on hydrogen while maintaining internal combustion. Key adaptations include replacing injectors to handle hydrogen, adjusting the air intake system for optimal air/gas mixture, and modifying combustion chambers.

Most of the original drivetrain (gearbox, transmission) is preserved, making integration easier.

This type of retrofit is particularly well-suited to heavy vehicles, leveraging proven technologies, minimizing transformation costs compared to full electrification, and maximizing existing production assets.

Hydrogen Vehicle Retrofitting in France: What Does the Law Say?

Officially authorized since March 2020 [8], hydrogen retrofitting in France is governed by strict regulations to ensure safety, performance, and durability.

Here’s what you need to know:

Eligible vehicles:

- Must be over 5 years old.

- Includes passenger cars, utility vehicles, heavy trucks, buses, or specialized machinery.

Mandatory homologation:

Each retrofit must be officially approved by regulatory authorities after a series of rigorous tests to guarantee:

- Continued safety of the vehicle.

- Stable performance meeting regulatory standards.

Technical requirements:

To be approved, retrofitted vehicles must meet specific criteria:

- Power output must be between 65% and 100% of the original vehicle’s power.

- Axle weight distribution must not vary by more than 10%.

- Total weight must remain within +20% of the original weight.

In conclusion, hydrogen engines—whether fuel cells or internal combustion—represent a compelling solution to decarbonize heavy-duty and intensive transportation, particularly in professional sectors and passenger transport.

Whether you are an industrial player, a municipality, or a transport company, choosing the right hydrogen technology will depend on your operational needs and your budget.

[1] H2 Mobile – Fuel Cells: How They Work, Advantages and Drawbacks

[2] Source Atawey – Behind The Pump: A Deep Dive into a Technological Revolution

[3) H2 Mobile – How Does a Hydrogen Engine Work?

[4] Source Atawey – Why Choose a Hydrogen Car? Key Benefits, Limitations, and Real-World Applications

[5] Source – Connaissance des Énergies – Hydrogen in Transportation

[6] Source GCK – Internal Combustion Engine

[7] Coalition Rétrofit H2

[8] Légifrance – Decree of March 13, 2020 on the Conditions for Converting Internal Combustion Engine Vehicles to Battery-Electric or Fuel Cell Electric Powertrains