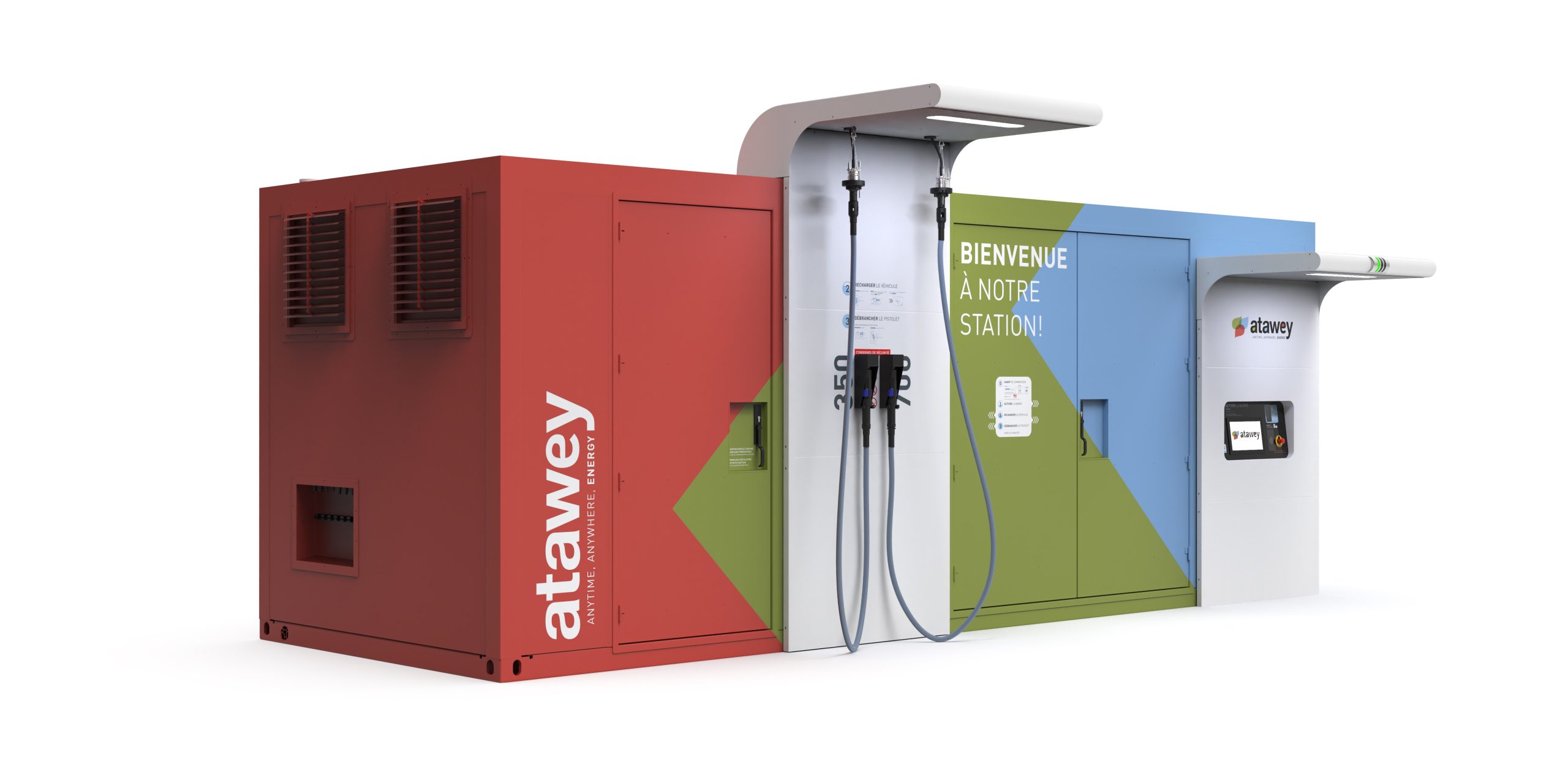

Atawey designs and deploys proven hydrogen station technologies, adaptable for a variety of applications, whether it’s decarbonizing vehicle fleets, powering construction sites, or supporting heavy and intensive mobility needs. Thanks to their modularity, flexibility, and scalability, Atawey’s stations seamlessly integrate into both your current and future projects.

At your Service

Why Choose an Atawey Hydrogen Station?

EXPERTISE

Atawey hydrogen stations are designed to grow with your needs. Whether you're starting with a small fleet or planning to scale up, our stations can be configured and expanded accordingly.

Our stations support a wide range of vehicles, including light-duty vehicles (taxis, vans), buses, trucks, and specialized equipment used in construction sites and warehouses.

Compact and pre-configured solutions enable quick commissioning, reducing both costs and lead times.

Atawey stations are designed to accommodate different hydrogen sources—whether from on-site electrolysis, tube trailers, or pipelines.

Tailored to Your Needs

Atawey Hydrogen Station Ranges

SOLUTIONSAll our stations are designed by our in-house R&D team to meet your exact needs, ensuring strict safety standards, high availability rates, and optimized Total Cost of Ownership (TCO).

01

Evolutive Hydrogen Stations

Atawey’s modular, scalable stations adapt to the different phases of a project, optimizing profitability while complying with AFIR regulations and supporting high-capacity needs.

Adjustable storage and distribution capacity

Integration with local energy infrastructures

Compatibility with fleets of all sizes

From 300 kg/d

to 2 t/d

💡 Ideal for: Local authorities, businesses, and transport operators looking for a sustainable, scalable solution for transit or captive fleets.

02

Compact Hydrogen Stations

Designed for maximum efficiency in minimal space, Atawey’s compact stations are perfect for projects with land constraints. Their small footprint and high performance make them an excellent entry point into decarbonized mobility.

These stations also feature a relocatable design, making them useful for:

Temporary deployment before a larger station is installed

Providing refueling for hydrogen vehicles while permanent infrastructure is being built

Serving as a satellite station for expanding refueling networks

Up to 300 kg/d

💡 Ideal for:

- Medium-capacity needs, such as light commercial vehicle fleets and small municipalities.

- Urban areas with limited space.

- Network expansion through satellite stations.

03

Mobile Hydrogen Stations

Mobile hydrogen stations provide flexible, on-demand solutions for temporary or remote needs. Easily transportable and quick to deploy, they ensure hydrogen refueling wherever it’s needed.

Up to 150 kg/d

💡 Ideal for:

- Zero-emission construction sites

- Temporary refueling when a station is under maintenance

- Logistics support in remote areas

- Events requiring clean mobility solutions

- Testing hydrogen vehicle prototypes

| Source | |||

| Distribution Capacity | |||

| Pressure Levels |

📞 Contact us for more details!

At your service

A Turnkey Solution for Your Hydrogen Projects

H2 STATIONSAtawey offers more than just hydrogen stations—we provide a 360° approach, guiding clients through every phase of their hydrogen project.

Feasibility studies

Needs assessment and expert consultation.

Fast installation

Pre-configured stations for seamless deployment.

Maintenance and monitoring

Ensuring long-term performance and reliability.

Mastering technology

Atawey's Proven Technologies: Robust and Reliable Solutions

EXPERTISETo ensure the reliability, safety, and performance of its hydrogen stations, Atawey relies on proven technologies and in-house developed tools. These innovations guarantee optimal station operation while complying with the industry’s most stringent standards and regulations.

Atawey’s Proven Hydrogen Technologies

To guarantee reliability, safety, and performance, Atawey leverages proven in-house technologies, ensuring seamless station operation while meeting the highest industry standards.

Made-in-Atawey Technologies & Tools

🛠️ ata’CONFIG – A dynamic station sizing tool.

🚀 ata’START – A rapid commissioning program.

✅ ata’CHECK – Daily self-testing program to monitor station health and prevent failures.

📊 ata’METRICS – A legally certified metrology system.

Compliant with the Most Stringent Industry Standards

Atawey designs its stations in full compliance with international regulations and proactively adapts to future regulatory changes to ensure safety, reliability, and performance.

📜 CE (European Conformity)

🛠️ SAEJ2601 & CEP fueling protocols (for hydrogen vehicle refueling)

⚙️ MC Formula (refueling protocol)

⚠️ HAZOP (Hazard and Operability Study) methodology

🔍 ICPE (Classified Installations for Environmental Protection)

Contact us

Ready to Take Your Hydrogen Project to the Next Level?

CONTACTWith its scalable, compact, and mobile stations, Atawey is the ideal partner for all your hydrogen needs.

📞 Contact an Atawey expert today to discuss your hydrogen project!

Questions & Answers

Atawey Hydrogen Stations

Q&AAtawey offers three types of hydrogen stations to match your specific needs:

- Evolutive stations – Ideal for high-traffic corridors and urban hubs (especially for AFIR-compliant stations).

- Compact stations – Designed for urban areas and space-constrained locations.

- Mobile stations – Perfect for temporary or remote needs, such as construction sites, testing, or events.

Each station is fully configurable based on your fleet size, location, and operational requirements.

Atawey’s compact and mobile stations are engineered for fast installation, thanks to their all-in-one containerized design and ata’START rapid commissioning program.

For scalable stations, commissioning depends on the project size and complexity, but most installations are operational within a few months after validation.

Atawey offers two main types of hydrogen infrastructure to suit different project needs:

- Hydrogen Production Stations

These stations produce, store, and distribute hydrogen on-site, often using electrolyzers powered by renewable energy sources such as solar or wind. They provide full energy independence and can supply excess hydrogen to satellite stations.

- Satellite Stations

These stations do not produce hydrogen but store and distribute hydrogen delivered (by container or pipeline) from a central production unit. By locating stations closer to users, satellite stations reduce logistical costs while minimizing environmental impact.

This hub-and-spoke model allows a single electrolyzer to supply multiple stations, optimizing investments and reducing Total Cost of Ownership (TCO).